CE Industrial Plastic Crushing Recycling Machine Series Plastic Crusher

Overview Package size per unit product 2600.00cm * 2250.00cm * 4200.00cm Gross weight per unit product 5000.000kg Produc

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | STC 380/600 400/800 500/800 630/1000 750/1200 |

| Raw Material | PVC/PP/PE |

| Structure | Top Feed |

| Knife Classification | Claw Knife Crusher |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Non-Computerized |

| Certification | CE, ISO9001:2008 |

| Capacity | 250kg/H |

| Guarantee | One Year |

| Application | PVC/PE/PP/ABS Shaped Material |

| Condition | New |

| Machine Type | Plastic Crusher |

| Weight (T) | 0.5 |

| Brand Name | Sino-Tech |

| Max.Production Capacity (Kg/H) | 600 |

| Key Selling Points | Key Selling Points |

| Dimension(L*W*H) | 2600*2250*4200 |

| Hydraulic Power (Kw) | 2.2 |

| Rotary Blades | 6 |

| Screen Size(mm) | 8-60 |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2022 |

| Transport Package | Plastic Film and Wooden Box |

| Specification | swp400 |

| Trademark | Sino |

| Origin | China |

| HS Code | 84772090 |

| Production Capacity | 250kg/H |

Packaging & Delivery

Package size per unit product 2600.00cm * 2250.00cm * 4200.00cm Gross weight per unit product 5000.000kgProduct Description

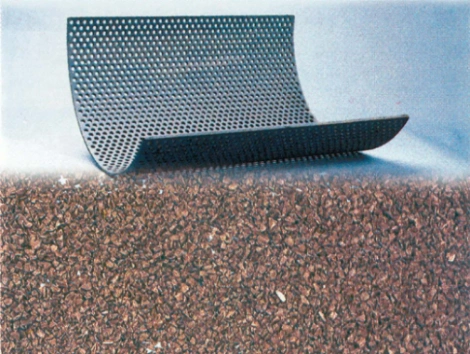

Industrial Plastic Crusher Crushing Machine

STC Series Crusher Machine is a high-efficiency and low energy consumption crusher. According to the characteristics of different materials, the crusher is equipped with a variety of rotor models for choosing. The diameter of the rotor ranges from 380mm to 750mm. A targeted rotor structure can be designed to achieve the best crushing effect. It adopts a special welding process for the overall steel structure to meet the demand for the materials which are not easily broken. Large rotor bearings, tool holders and rotors are combined with standard V-shaped cutting technology, which is beneficial to improve cutting and recycling efficiency and reduce the dust content in recycled materials.Main Features1.This machine is suitable for crush mang kind of plastic film and other soft materials.2.Low energy consumption, easy to install, operate and maintain3.Change the different diameter sieve, can get different size of final scrap.4.Machine automatic stop when the cutting blades are exposed.

Application:

Sinotech crusher is mainly used for crushing long PVC/PE/PP/ABS shaped material, plastic door and window, plastic pipe, plastic sheet, plastic plate etc. You can put the material on time, no need to cut into pieces.The crushed scraps can be put into the pulverizer to make powders.

Product Parameters

| STC Series Crusher Machine | ||||||

| Model | 380/600 | 400/800 | 500/800 | 630/1000 | 750/1200 | |

| Motor Power(Kw) | 22/30 | 30 | 37 | 55/75 | 90/110 | |

| Rotary Blades | 6 | 6 | 6 | 6/10 | 10/14 | |

| Fixed Blades | 2 | 4 | 4 | 2 | 4 | |

| Rotor Size(mm) | Ф380 | Ф400 | Ф500 | Ф630 | Ф750 | |

| Inter Size (mm) | 450*500 | 1000*700 | 1000*850 | 1200*950 | 1200*1000 | |

| Screen Size (mm) | Ф8-Ф20 | Ф8-Ф60 | Ф8-Ф60 | Ф8-Ф60 | Ф8-Ф60 | |

| Hydraulic Power (Kw) | 1.5 | 1.5 | 1.5 | 2.2 | ||

| Dimension (L×W×H mm) | 1500*1100*2100 | 1730*1365*3200 | 2000*1620*3400 | 2300*1950*3800 | 2600*2250*4200 | |

Detailed Photos

Screen Blade Hole size can according to customer standard Blade material is SKD-11 materials, from Japan "V" type structure Rotor /Frame Suitable for crushing pe pp films, bags, etc. Through nitrify treatment, ensure long service life time.Plane Flow

Company Profile

Certifications

Packaging & Shipping

FAQ

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer's needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time

Related Products

-

![Low-Temperature Single Cone Conical Screw Spiral Belt Vacuum Dry Drying Equipment for Vegetable Juice, Coffee, Coconut Milk, Pigment, PAC, Zinc, Yeast, Blood]()

Low-Temperature Single Cone Conical Screw Spiral Belt Vacuum Dry Drying Equipment for Vegetable Juice, Coffee, Coconut Milk, Pigment, PAC, Zinc, Yeast, Blood

-

![Building Material Gypsum Board Machinery Construction Equipment]()

Building Material Gypsum Board Machinery Construction Equipment

-

![Building Material Shops Cement EPS Composite Lightweight Partition Board Equipment Factory]()

Building Material Shops Cement EPS Composite Lightweight Partition Board Equipment Factory

-

![Kcd Type 300-600kg Building Crane Material Lifting Equipment]()

Kcd Type 300-600kg Building Crane Material Lifting Equipment