Tailings Treatment Slurry Pump for Metallurgy, Mineral Processing, Benification, Electric Power, Coal

Product Description Slurry pumps are designed for heavy-wearing and heavy-duty uses like the transportation of abrasive

Send your inquiryDESCRIPTION

Basic Info

| Working Pressure | High Pressure Pump |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Horizontal Pump |

| Pump Casing Combined | Horizontal Split Pumps |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Pumps, Condensate Pump, Ash Pumps, Circulating Pump |

| OEM | Offered |

| Pump Parts Engineering | up on Need |

| Materials | Metal or Rubber Liner |

| Transport Package | Wooden Packing |

| Specification | Large flow High effiency |

| Trademark | Kingda |

| Origin | China |

| HS Code | 841370 |

| Production Capacity | 2000 Mt/Month |

Product Description

Product Description

Slurry pumps are designed for heavy-wearing and heavy-duty uses like the transportation of abrasive fluid and corrosive Slurry in industries such as mining, dredging steel and sewage treatment.

It is a kind of machinery that increases the energy of solid and liquid mixed fluid by means of centrifugal force (the rotation of the impeller of the pump), and converts energy into the kinetic energy and potential energy of the Slurry.Slurry pumps differ from the other pumps in many aspects like design and materials,when choosing a slurry pump you need take everything into consideration, otherwise it will cause the service life of the slurry pump to be greatly reduced.

Slurry pump structure

Structural design of metal lining and rubber lining

Slurry Pump Accessories

Technical parameters of slurry pump

| Model | Allowable Max.Power(Kw) | Clear Water Performance | Impeller | |||||

| Capacity Q | Head H(m) | Speed n(r/min) | Top Efficiency η% | NPSH | Diameter D(mm) | |||

| M³/h | L/s | |||||||

| M20KSH-B | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| M40KSH-B | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| M50KSH-C | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| M75KSH-C | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| M100KSH-D | 60 | |||||||

| R100KSH-D | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| M100KSH-E | 120 | |||||||

| M150KSH-E | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| M150KSH-R | 300 | |||||||

| M200KSH-ST | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| M250KSH-ST | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

| M300KSH-ST | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| M350KSH-TU | 1200 | 1638-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1065 |

| M450KSH-U | 1200 | 2700-5400 | 750-1500 | 13-55 | 200-375 | 88 | 4.5-9.5 | 1375 |

| M550KSH-X | 3000 | 2250-7740 | 625-2150 | 14-68 | 200-400 | 82 | 4.5-9.5 | 1615 |

| R550KSH-X | ||||||||

| R650KSH-X | 3000 | 3420-11880 | 950-3300 | 10-60 | 150-350 | 86 | 4.5-9.5 | 1810 |

| M650KSH-X | ||||||||

| Metal Lined Pumps | Rubber Lined Pumps | ||

| Part Description | Material Specification | Part Description | Material Specification |

| Base | Cast Iron | Base | Cast Iron |

| Shaft | 4140 High Tensile Steel | Shaft | 4140 High Tensile Steel |

| Bearing Assembly | Timken(Cast Iron Body) | Bearing Assembly | Timken(Cast Iron Body) |

| Shaft Sleeve | 420 Stainless Steel | Shaft Sleeve | 420 Stainless Steel |

| pump Casing | Cast Iron | pump Casing | Cast Iron |

| Frame Plate Liner | 27% Chrome White Iron | Frame Plate Liner Insert | Rubber |

| Volute Liner | 27% Chrome White Iron | Cover Plate Liner | Rubber |

| Impeller | 27% Chrome White Iron | Impeller | Rubber Coated High Tensile Steel |

| Throat Bush | 27% Chrome White Iron | Throat Bush | Rubber |

| Joint Ring | Rubber | Cover Plate | Cast Iron |

| Cover Plate | Cast Iron | Stuffing Box | Cast Iron |

| Stuffing Box | Cast Iron | Expeller | 27% Chrome White Iron |

| Expeller | 27% Chrome White Iron | Expeller Ring | Natural Rubber |

| Expeller Ring | Natural Rubber | Bolts | Zinc Plated Steel |

| Bolts | Zinc Plated Steel | O-rings | Nitrile Rubber |

| O-rings | Nitrile Rubber | Seals | Rubber |

| Seals | Rubber | ||

Slurry pump Features:1)High concentration, volume concentration reach to 60%, weight concentration reach to 70%; 2)Comprehensive performance is good, high head: long distance and high head transportion, single set head can reach to max 120m, and can be used in series to satisfy much higher head requirements; 3)High flow rate capacity: can be reached 3400m3/h; 4)Good passing ability:gravel pump max passing particles size is 380mm; 5)Diameter size:outlet size from 1" to 22" 6)Widely application: all slurry, mud and bad corrosive medium can be transported, widely used in industry of mining, electrical power, metallurgy,coal, construction etc. 7)High corrosion, abrasion resistance widely material optional: metal flow parts including: (Cr27Mo),(Cr30MoNi),(Cr30MoNiCu)and rubber material etc. PH value 1.0-14. 8)Our company passed ISO certificate and all of our pumps pass CE certificate, comply with international standards. 9)Driving engine of motor and diesel are available; 10)Kinds of driving method satisfy different space need on site: CR, CZ, CV, ZV;

Qiangda group has the sole impurity pump research lab in China that serves the pump industry, specializing in the research work of pumps performance, wear mechanism, wear-resistant materials and new product development. To make full use of the technology, an independent technology center was set up in the factory, focusing on cooperation with top domestic colleges and universities such as Tsinghua University, a fast product transformation from the latest technology is released.At the same time, from the perspective of sustainable development, the company strictly ensures the proportion of product R&D investment. Which injects impetus to the renewal of products . Now Kingda has also 6 series of nearly 100 varieties of high-efficiency and energy-saving new products. It has embarked a new career on a road of "technology introduction, digestion and absorption, innovation and improvement".

Shijiazhuang Kingda Pump industry group co.limited is the largest professional manufacturer of slurry pumps,sewage pumps and submersible pumps in China.All products are mainly supplied to mining,metallurgy,public works,coal,petroleumChemical,building material and other national economic departments.The products are sold well all China and far to Iran,Saudi,Uzbekistan and Russia more than 40 countries in the world.

Professional Oversea teams

In order to better serve overseas customers, Qiangda establish a new and separated oversea department in 2021, who will actively explore the international market relying on domestic production bases .The service team of the new department has decades' experience in overseas trade. they have a thorough understanding of products and welcome any consultation. Choose Qiangda and pump strong power to your career.

Customized solution for every Pump need

Qiangda group, in line with the concept of serving customers and developing together with customers, provides customized solutions for every slurry pump needs. For years, we learn from the customer and better served them in return. Qiangda Group focus on large scale slurry pumps, pumps strong power to your career.

In terms of equipment quality

Provide clients with high-quality products that meet relevant national standards, contract requirements, and customer's design and application requirements. And implement life-long service. A third-party supervision system can be implemented for important products.

In terms of delivery

Perform the delivery responsibilities on time, and transport in the most convenient way to minimize the time for customers to get the product

In terms of technical service

Provide users with important technical information for operation and maintenance. Combining with the network and remotely, provide technical and business training for equipment installation, commissioning, operation, and maintenance. When necessary, experienced engineering and technical personnel could be sent to provide on-site technical services in time . After receiving the user's complain of the quality problem , It is guaranteed to reply within 24 hours and provide a solution within 48 hours, and the service will not stop if the user is not satisfied with the solution.

Related Products

-

![Three Drum Mining Drying Equipment, Rotary Drum Dryer for Silica Sand, Limestone, Coal, Calcium Carbonate, Feed Dregs]()

Three Drum Mining Drying Equipment, Rotary Drum Dryer for Silica Sand, Limestone, Coal, Calcium Carbonate, Feed Dregs

-

![New Type Building Material 1071 Corrugated and 960 Glazed Tile Colored Metal Iron Panel Double Layer Roll Forming Machine Equipment]()

New Type Building Material 1071 Corrugated and 960 Glazed Tile Colored Metal Iron Panel Double Layer Roll Forming Machine Equipment

-

![Food Milk Vacuum Freeze Drying Equipment for Sale]()

Food Milk Vacuum Freeze Drying Equipment for Sale

-

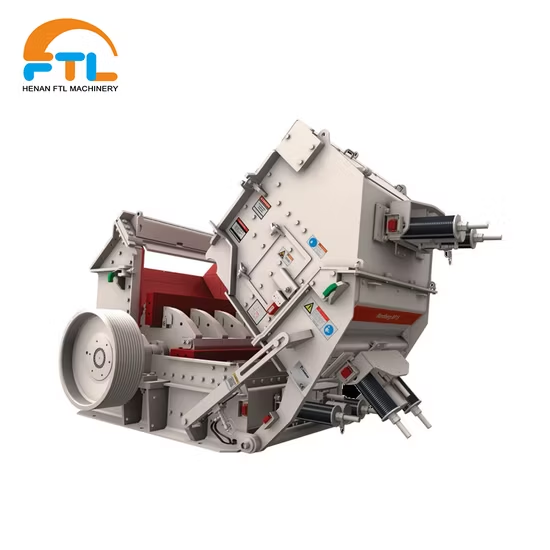

![Granite Crushing Machine PF Series Impact Crusher for Sale]()

Granite Crushing Machine PF Series Impact Crusher for Sale